Printing & production

At our state-of-the-art production and printing facilities in Poznań, Poland, as well as those in Blackpool and Banbury in the UK, we are committed to responsible production. Through continuous improvement initiatives, we actively aim to reduce our corporate carbon footprint, minimise waste, and deliver lower impact printing solutions.

Drive2Digital

Our Drive2Digital initiative, through which we transitioned to 31% digital print in 2023, significantly improves our environmental impact. This strategic shift reduces waste and enhances production efficiency. For instance, our acquisition of a Direct-to-Film printer in 2023 supports digital transfer processes, streamlining operations and minimising material waste compared to more traditional printing methods.

Certified printing techniques

As part of our commitment to substantiating our sustainability claims, we have certified several of our branding techniques, allowing us to offer fully certified products from source to branding. This includes certified screen print, transfer, and embroidery on our GOTS and GRS-certified products, ensuring that every step of our process meets strict certification standards.

Inks library & water-based inks

At our Polish operations, we've optimised our ink-management process with an advanced Ink-Library system. This system tracks ink inventory, ensuring that leftover inks from screen printing are collected, tested for PMS colour accuracy, and stored for future use. Before creating new ink mixes, we first check the Ink-Library to utilise existing resources. This approach reduced ink waste by 38% in 2023, with further improvements expected in 2024. Additionally, in the UK, we've introduced water-based inks for screen printing, which will also be rolled out in Poland in 2025.

Reusing our waste

In Blackpool, we’ve achieved an impressive 95% recycling rate for production waste, repurposing materials into Americano cups, Brite® mouse mats, and coasters. In 2024, our Banbury facility will advance its sustainability efforts by implementing an in-situ plastic recycling process, turning used plastic into new material and closing the loop in our operations. We aim to prevent 22,000 kg of waste, significantly enhancing our environmental impact.

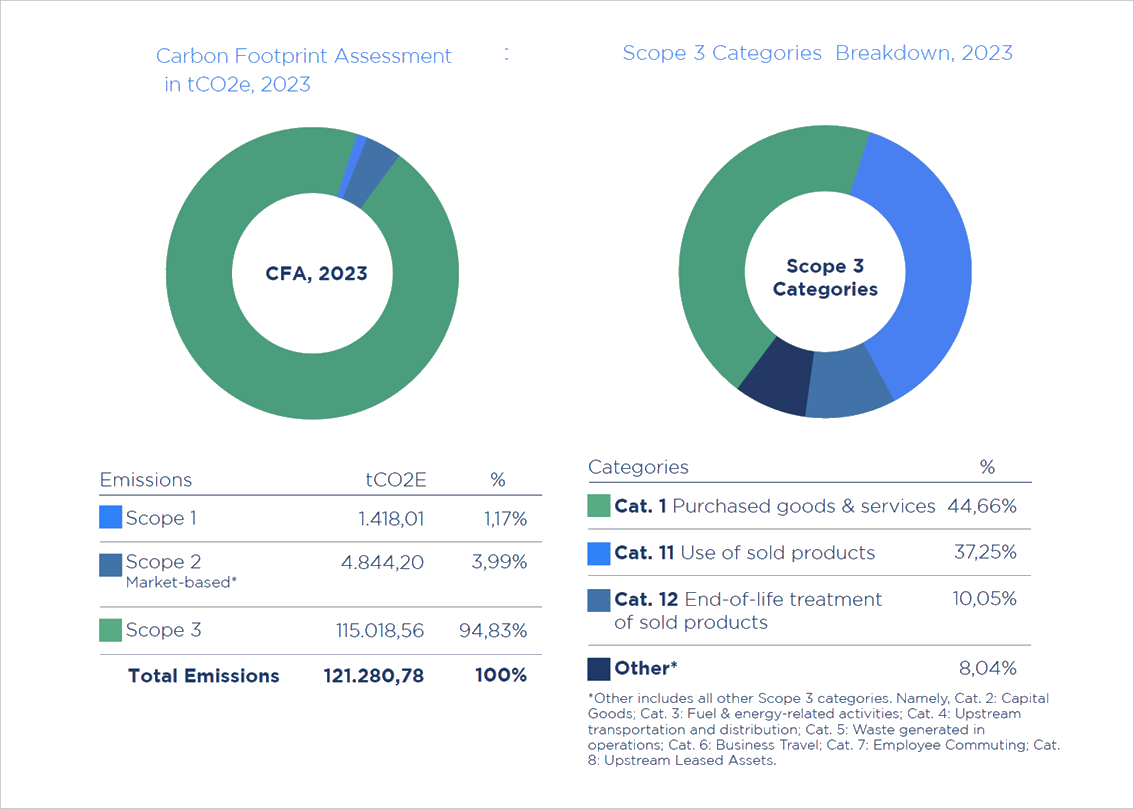

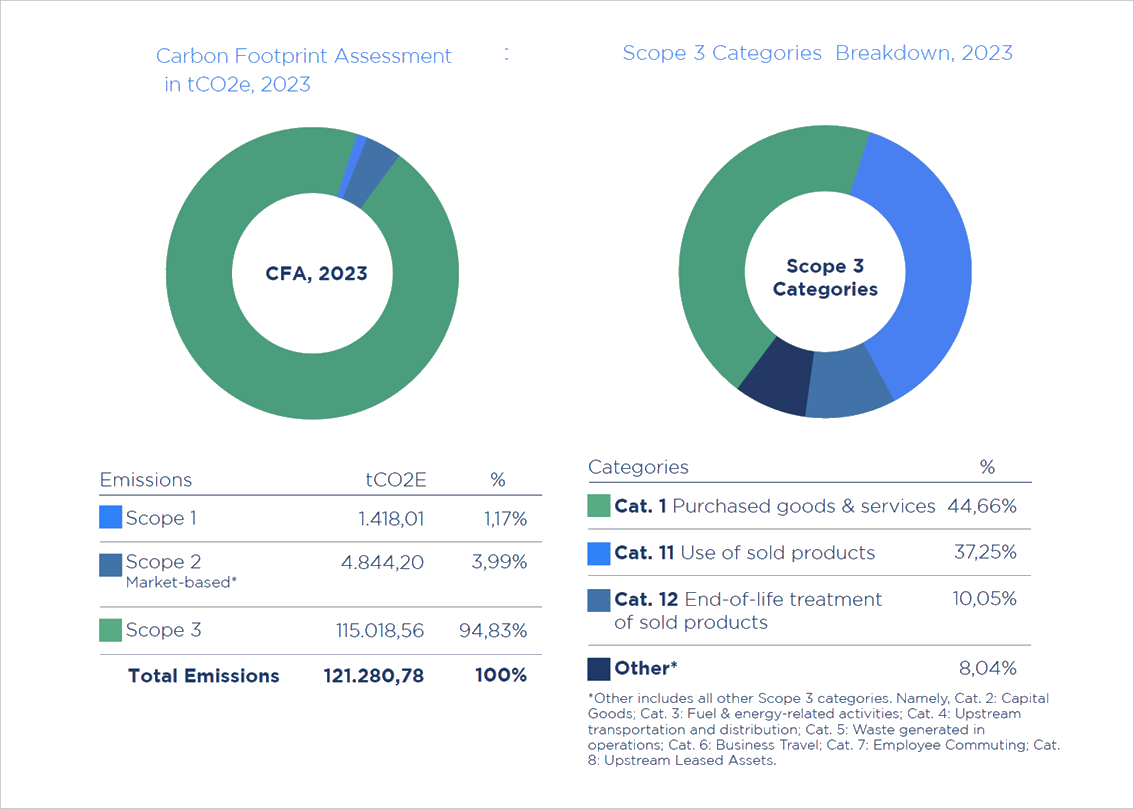

Corporate carbon footprint

Aligned with our double materiality assessment and the Paris Agreement, we aim to mitigate climate change by reducing greenhouse gas emissions and improving energy efficiency. In 2023, we recalibrated our Scope 1, 2, and 3 emissions and implemented key sustainability measures: PF Poland cut heating tunnel energy use by 70% with smart standby heating and began transitioning to LED lighting; Banbury, UK upgraded to LED exposure units and double-glazed windows; and Blackpool replaced an energy-intensive laser with a fibre laser that uses 90% less energy, optimised facility layout and additional cobots . Additionally, we deployed electric vans and remote-fix cobots, further reducing emissions across our value chain.